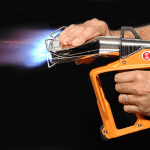

Ripack Supplies® specialises in shrink films and accessories for high-volume packaging. The use of shrink films requires a high-performance heat source, provided by Ripack® shrink guns, an essential complementary product. To ensure optimum, safe shrinking, the choice of gas is a key factor.

Why use propane or biopropane?

Propane and biopropane are the only options recommended for safe, efficient use of heat-shrinking equipment.

- Propane: It offers high heat output and stable combustion, guaranteeing rapid, even shrinkage of heat shrink films.

- Biopropane: Biopropane: An environmentally-friendly alternative, it is produced from renewable resources and reduces CO₂ emissions by 70% compared with fossil propane. While maintaining the integrity of Ripack® shrink guns (no degradation).

What type of gas cylinder should I choose?

The propane cylinders used for heat shrinking are generally available in different sizes. Because it is essential to ensure their stability and safety when moving around on site, opt for a standard 11 to 15 kg cylinder so that you can transport it using our 750 all-terrain cylinder trolley.

Offered by Ripack Supplies®, it’s the ideal solution for facilitating mobility and improving operator safety. Equipped with large wheels for optimum manoeuvrability on all types of terrain, it incorporates a storage rack for essential accessories and a hose locking system, extending the life of the equipment.

Why not use butane with Ripack® shrink guns?

Butane should not be used for several reasons :

- Insufficient pressure : It provides a lower pressure than propane, affecting heating performance.

- Problems at low temperatures : It becomes ineffective in cold weather, making it unreliable.

- Risk of accelerated wear and tear : It can lead to internal deposits that prevent equipment from operating properly.

Natural gas: a possible alternative?

Under certain conditions, natural gas can be used with Ripack® guns via a specific adaptation kit. However, there are some constraints to its use:

- Pressure required : between 0.5 and 3 bars. The network may need to be adapted.

- Higher consumption : A Ripack® 3000 gun consumes around 5.2 kg/h of bottled propane, but will require 11 kg/h of natural gas for a pressure of 3 bars.

- Reduced power : Natural gas provides less intense heating, resulting in longer shrinkage times.

Heat shrink films and gas compatibilityt

The shrink wrap supplied by Ripack Supplies® require an effective heat source to guarantee even, resistant shrinkage. The use of propane or biopropane ensures a powerful and stable flame, which is essential for optimal results on industrial packaging and large-volume protection, especially if the work is carried out outdoors.

The use of propane or biopropane is essential to guarantee the performance and safety of heat-shrinking operations with Ripack Supplies® equipment. The use of butane is strictly discouraged due to its technical incompatibility, while natural gas can be considered under specific conditions.

The integration of the 750 bottle trolley further facilitates mobility and safety on site by transporting your 13kg bottle.

If you have any questions about your choice of gas or how to adapt your equipment, contact your dealer. They’ll be happy to help you with all your business needs!