Heat shrink wrapping is now an essential solution for protecting, packaging, or securing goods of all sizes. Used across many sectors, logistics, industry, marine, construction, or outdoor storage, it provides effective protection against moisture, dust, and impacts.

However, achieving optimal results requires choosing heat shrink equipment that is truly adapted to your activity. Power, safety, ergonomics, and consumables are all key criteria to consider in order to work efficiently and safely.

Understand your needs before choosing equipment

Before selecting heat shrink equipment, it is essential to clearly define your intended use. Not all applications require the same type of equipment.

Ask yourself the right questions:

- What types of volumes need to be protected? (pallets, machinery, oversized structures, boats, industrial modules)

- How often will the equipment be used? (occasional, regular, or intensive use)

- Will you be working indoors, outdoors, or in demanding climatic conditions?

These factors directly influence the choice of shrink gun, shrink film, and required accessories.

Choosing the right heat shrink gun

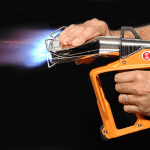

The heat shrink gun is the central tool of the system. Its purpose is to heat the film so that it shrinks evenly around the item being protected.

Several criteria should be considered:

Power and performance

A sufficiently powerful gun enables fast and uniform shrinking, even over large surfaces. For large volumes or frequent use, it is recommended to choose professional equipment designed to maintain consistent performance over time.

The Ripack 3000 is a modular, robust heat shrink gun designed for intensive use. It is compatible with an extension system that improves access to high or low areas while enhancing ergonomics.

When combined with the S33 extension, it becomes the Ripack 3000+, allowing operators to work comfortably from ground level without excessive effort and reducing the risk of musculoskeletal disorders during prolonged use.

Ergonomics

Good equipment must be easy to handle, well-balanced, and comfortable to use. Ergonomics are essential to reduce operator fatigue, especially during long work sessions or repetitive applications.

With the Ripack 3000, specific extensions can be added to work at greater distances or different heights without awkward postures, helping to reduce musculoskeletal strain.

For even greater comfort, the Ripack arm support can be attached to the Ripack 3000 (or Ripack 3000+). It distributes the weight of the gun and its extensions across the forearm rather than solely on the wrist, making intensive tasks less tiring and significantly improving overall operator ergonomics.

Built-in safety

Heat shrink wrapping involves the use of heat and gas. Professional equipment therefore integrates essential safety features, such as nozzle cooling systems, which significantly reduce the risk of burns and enhance operator safety in the field.

Choosing the right heat shrink film

The film plays a key role in the final result and must be selected based on:

- the size and shape of the items to be covered,

- the required level of protection,

- the storage environment (indoor or outdoor).

Professional heat shrink films are available in various thicknesses and widths to suit all configurations. High-quality film ensures uniform shrinking, strong mechanical resistance, and long-lasting protection of goods.

If you are unsure which equipment is best suited to your needs, don’t hesitate to use our configurator.

Gas selection: a key factor not to overlook

The gas used directly affects shrink quality and operational safety. Propane is commonly recommended for its stability and thermal efficiency. Alternative solutions such as biopropane also make it possible to combine high performance with a more responsible approach.

Well-designed equipment ensures controlled combustion, consistent heat output, and safer operation for the user.

Consider the complete installation

Heat shrink equipment is not limited to the gun alone. For safe and comfortable use, it is recommended to consider the entire workstation:

- suitable hoses,

- pressure regulator,

- 750 cylinder trolley to facilitate movement,

- complementary accessories to improve ergonomics, such as a safety cutter, hose reel, Calpack pallet raiser, arm support, and transport support.

Complete solutions save time, secure the installation, and optimize daily working conditions.

Adapt equipment to frequency of use

For occasional use, a simple setup may be sufficient. However, for regular or intensive use, it is preferable to invest in robust equipment designed to last and maintain a high level of performance without compromising safety.

A well-chosen professional system allows faster work, cleaner results, and reduced risk of incidents.

Conclusion: making the right choice to work efficiently and safely

Choosing heat shrink equipment suited to your activity means finding the right balance between performance, safety, and ease of use. By clearly defining your needs and selecting a high-performance, safe shrink gun, appropriate film, and a complete installation, you can optimize your shrink-wrapping operations while protecting operators.

Thanks to its recognized expertise in heat shrink solutions, Ripack Supplies offers large-volume systems designed to meet professional requirements across all industries, an effective choice for working efficiently, sustainably, and safely.