Heat shrink wrapping is now an essential solution for protecting, packaging, or securing goods of all sizes. Used across many sectors, logistics, industry, marine, construction, or outdoor storage, it provides […]

Our ventilation grids let your

confined

spaces and equipment breathe

Complete protection

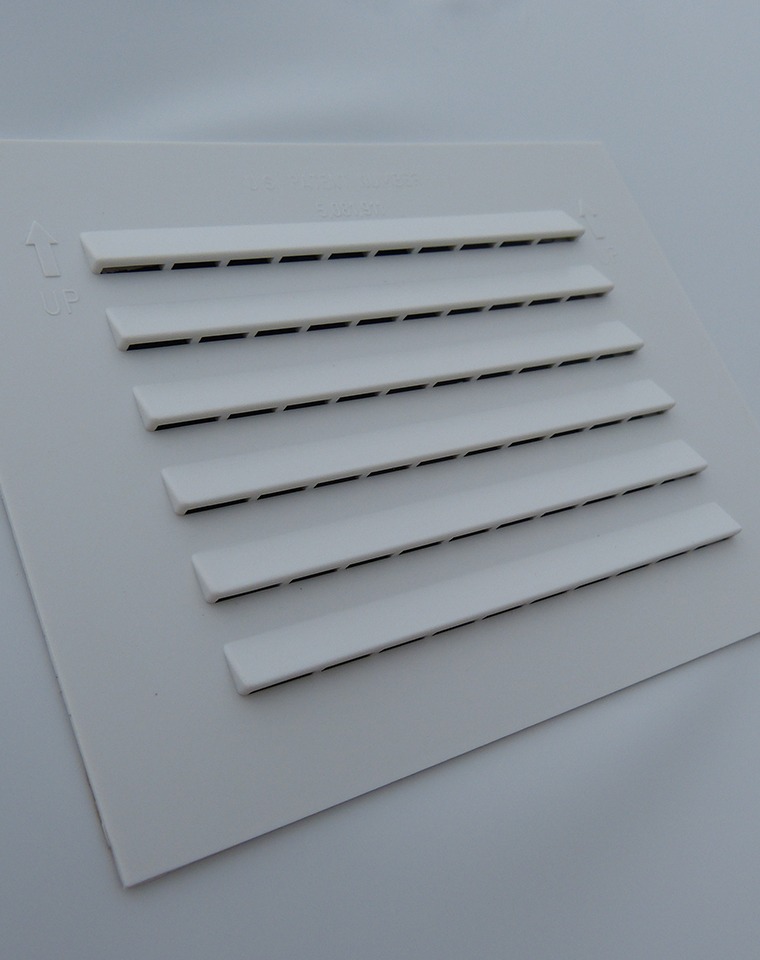

For optimum long-term storage, aeration grids for shrink film play an essential role in allowing air to circulate beneath the film. Ripack Supplies® self-adhesive aeration grids are designed to be strategically placed on either side of a winterized boat or any equipment protected by shrink film. Installed at two-meter intervals, these air intakes encourage the creation of air currents, preventing common problems such as unpleasant odors, humidity and mildew.

Shrink-wrap ventilation grids are particularly recommended for efficient air purification in confined spaces. In fact, the more ventilation grids you install, the better the air renewal will be, guaranteeing a dry, odor-free environment for your stored items. This is crucial when it comes to preserving boats during winter storage, or industrial equipment under film.

Ripack Supplies® self-adhesive aeration grids are easy to install and offer a practical solution for maintaining constant air circulation. Their adhesive properties ensure that they stay in place even in difficult conditions, ensuring continuous performance without the need for frequent readjustments. The regular arrangement of these grids across the entire surface of the shrink film is an effective strategy for preventing condensation build-up, a problem often encountered during prolonged storage.

By investing in quality ventilation grids for your shrink films, you’re not only protecting your goods from moisture and mildew, you’re also extending their lifespan. A well-ventilated environment with adequate air intakes means less risk of deterioration and optimal storage conditions.

Easy to

install

Ripack Supplies® self-adhesive ventilation grids are designed for quick and easy installation. Here’s how to install them:

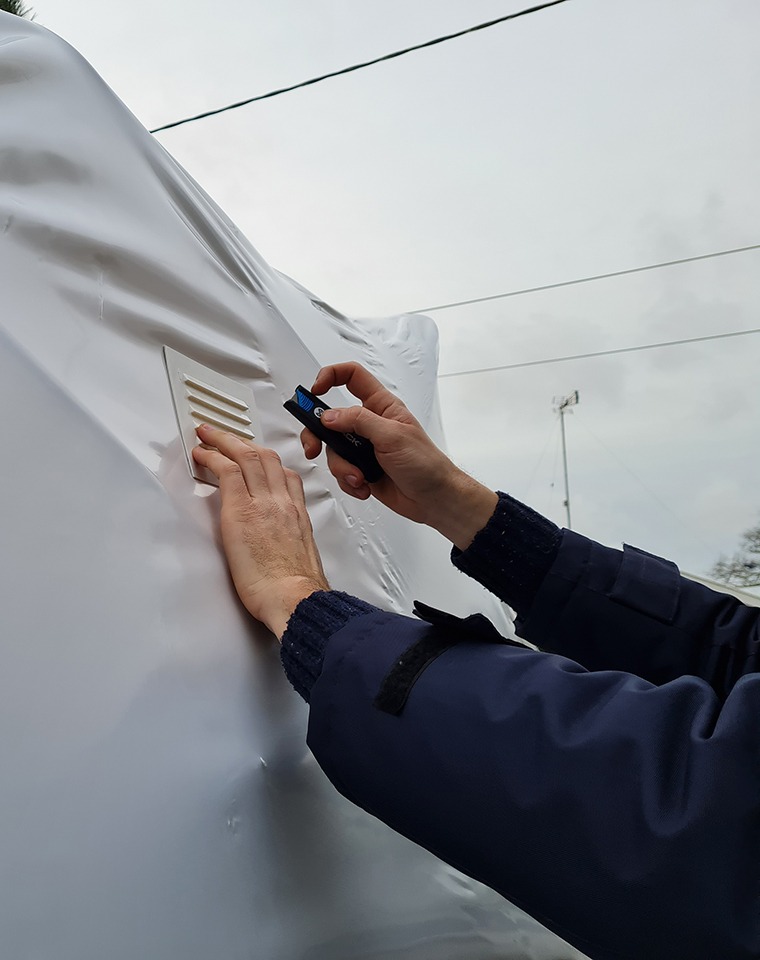

– Pre-positioning: Place the grid in its final location to measure the required cut-out. Cut the shrink film to the size of the grille, making sure to keep the film at the adhesive areas.

– Removing protection : Once the cut has been made, remove the protectors from the adhesive areas of the grid.

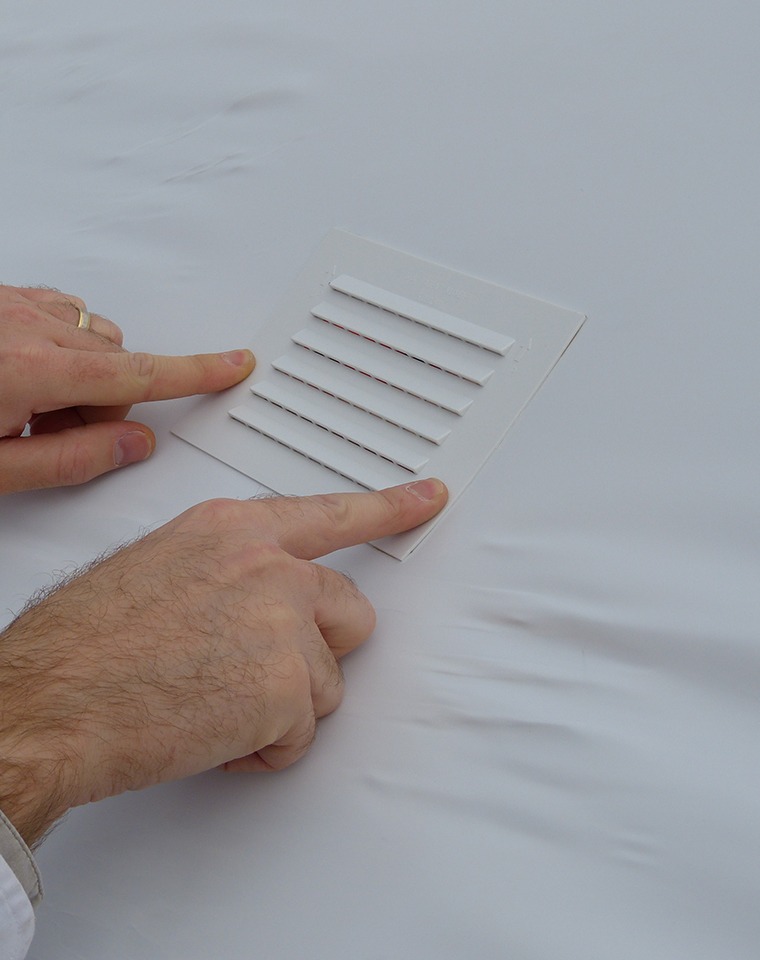

– Applying the grid: Stick the adhesive air intakes to the cut-out area to clean the air in your confined space. Press firmly on the adhesive sides of the grids to ensure a long-lasting hold.

– Rigidity and ease of use: Thanks to their rigid design, ventilation grids fit easily in one hand, making them easy to position.

These ventilation grids for shrink film are essential for avoiding problems of dampness, mildew and unpleasant odors, especially when it comes to prolonged storage. By providing constant ventilation, they ensure that the air remains cool and dry beneath the film, effectively protecting stored goods.

Ripack Supplies® self-adhesive ventilation grids are not only practical, but also robust. Their rapid installation and reliable adhesion guarantee long-lasting performance. By ensuring good air circulation, they help preserve boats, equipment and other shrink-wrapped items, maintaining a healthy, well-ventilated environment.